Print and Apply

Nautilus Systems, Inc. (NSI) offers multiple options for systems that offer print and apply both on demand or for batch production.

LC100i Applicator

The LC100i is our on-demand print and apply system incorporating our specialized peel technology with high quality (600 dpi) thermal transfer printing.

To view all LC100i Print and Apply Options CLICK HERE

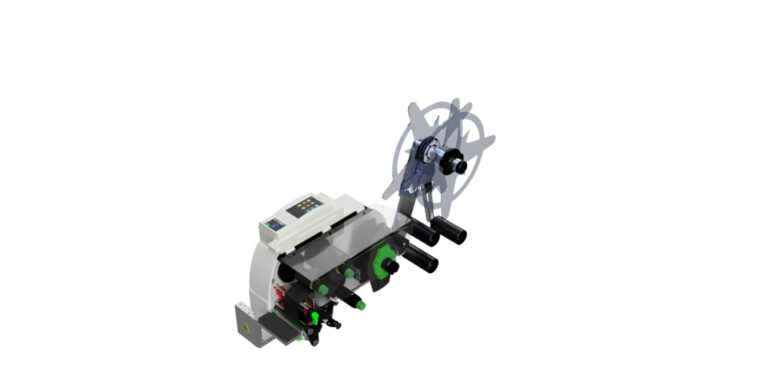

PL1XX-TTP Applicator

Our Thermal Transfer Print (TTP) systems combine a PL Series Applicator or Feeder with a thermal transfer printer. Print quality in 300 or 600 dpi is available. The TTP systems are best for batch printing operations that require precision placement of the label.

To view all PL Series Applicator with TTP Options CLICK HERE

LC100r Feeder

The LC100r is our on-demand print and peel system incorporating our specialized peel technology with high quality (600 dpi) thermal transfer printing.

To view all LC100r Feed and Peel Options CLICK HERE

FLEX Tube Pro

The FLEX Tube Pro is our standard system for automatically feeding Tubes or Vials from bulk storage, labeling the Tubes, and placing the labeled Tubes into a bin for removal by an Operator or to downstream automation for subsequent operations.

For more information about the FLEX Tube Pro CLICK HERE.