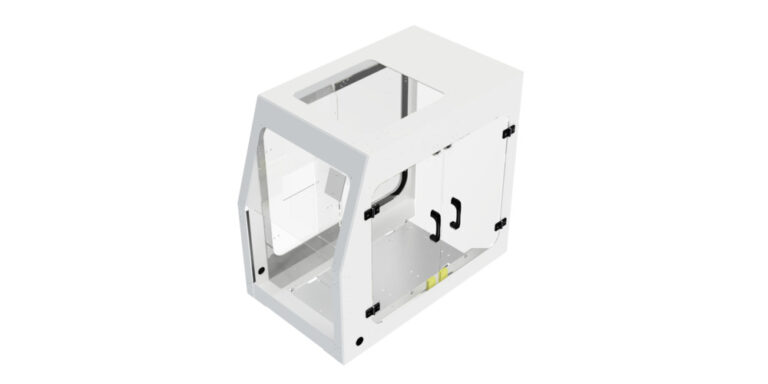

Description

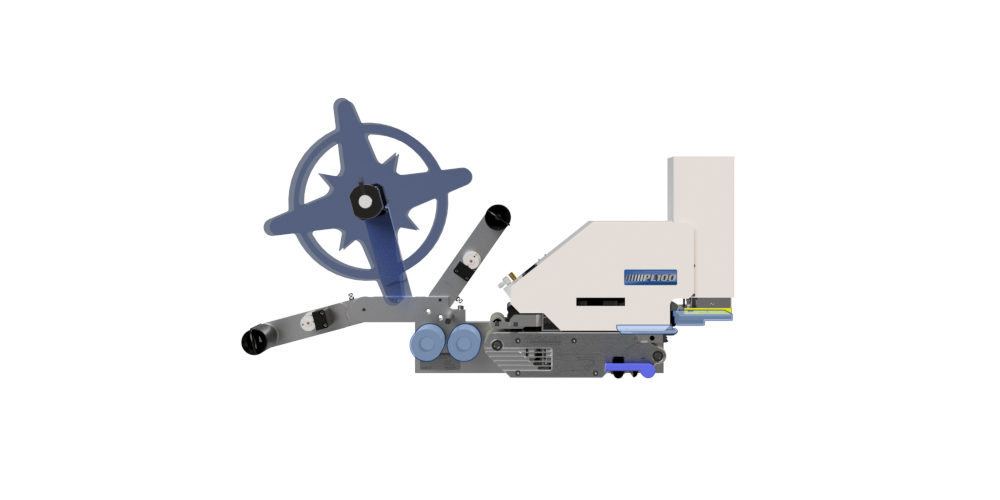

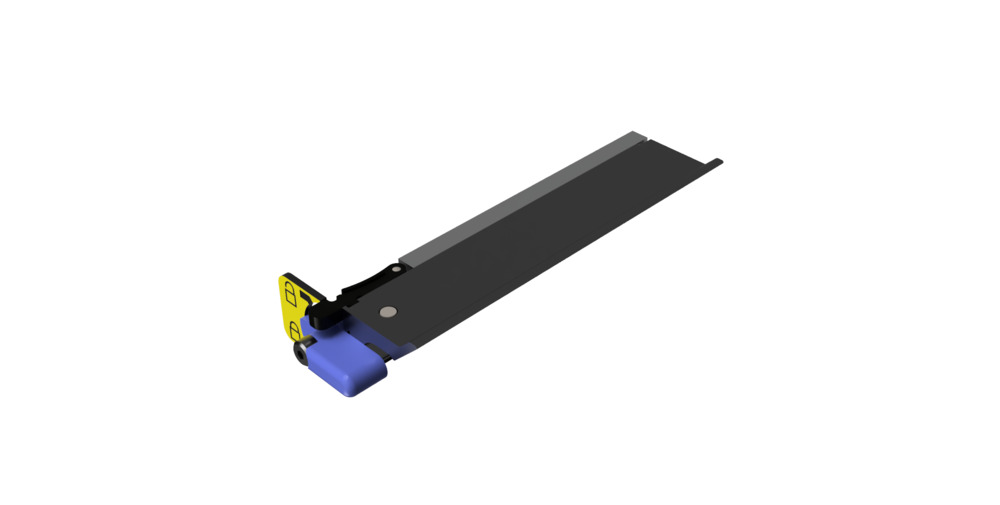

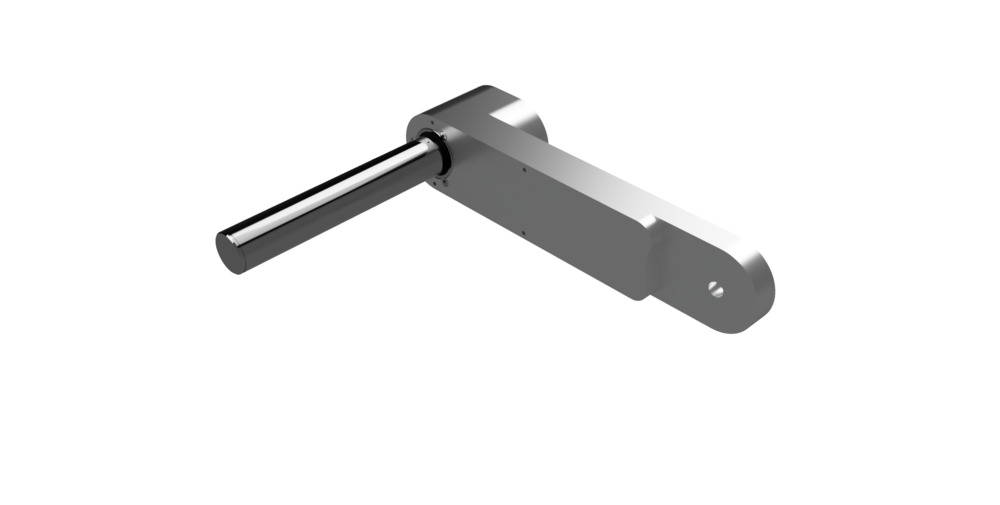

This Tamp configuration is available for either standard PL100 or PL100EP (extreme precision) Applicators. It is intended for components up to 50 x 50mm in size. This Tamp configuration provides the unique function of removing the adhesive component from the liner on one plane and then rotating the adhesive component 90 degrees to reposition the adhesive component on a plane perpendicular to the peel surface with the exposed adhesive surface facing away from the vacuum chuck. The RT90 can be configured with various lengths of stroke up to 175mm. This configuration allows the PL100 unit to be mounted in the conventional orientation (horizontal plane) even though the adhesive component application surface is a vertical plane.

Features

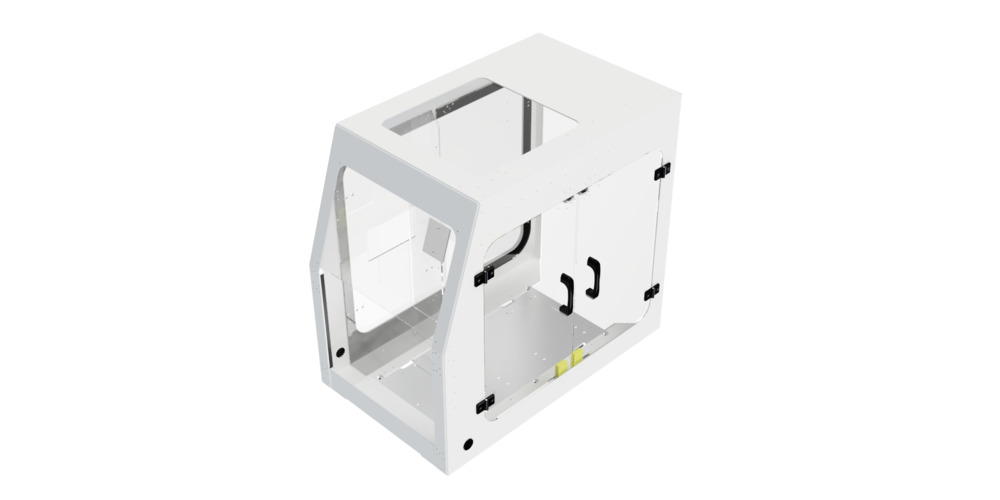

- Base Unit includes Integrated RT90 Tamp, Payoff, and Powered Take-Up (Rewind)

- Configured for Integration into Automation

- Rapid Changeover Features

- Maximum Affordability

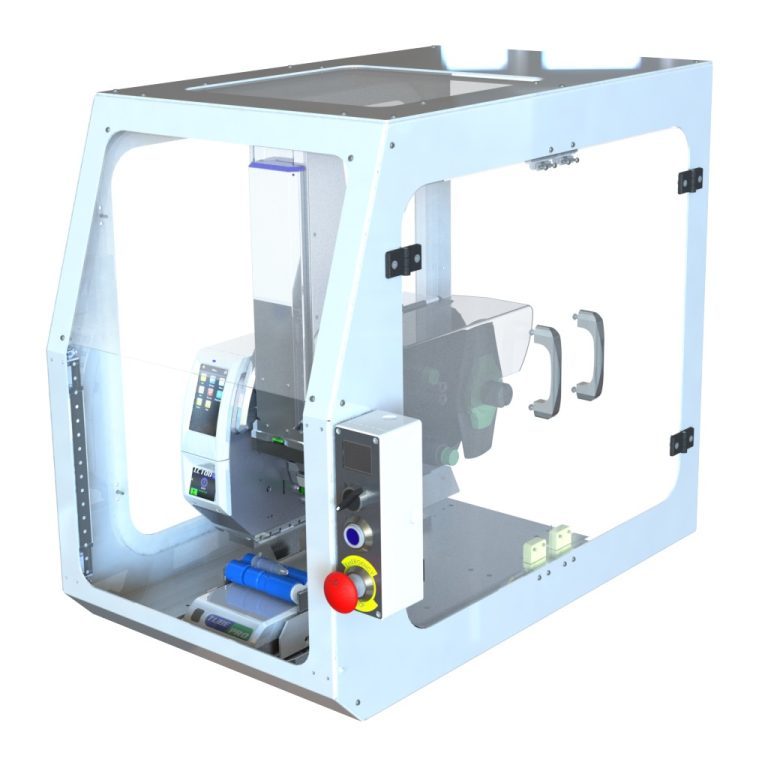

- 100 x 100mm Component Capacity

- Any Shape, Any Material, Multiple Simultaneous Placements

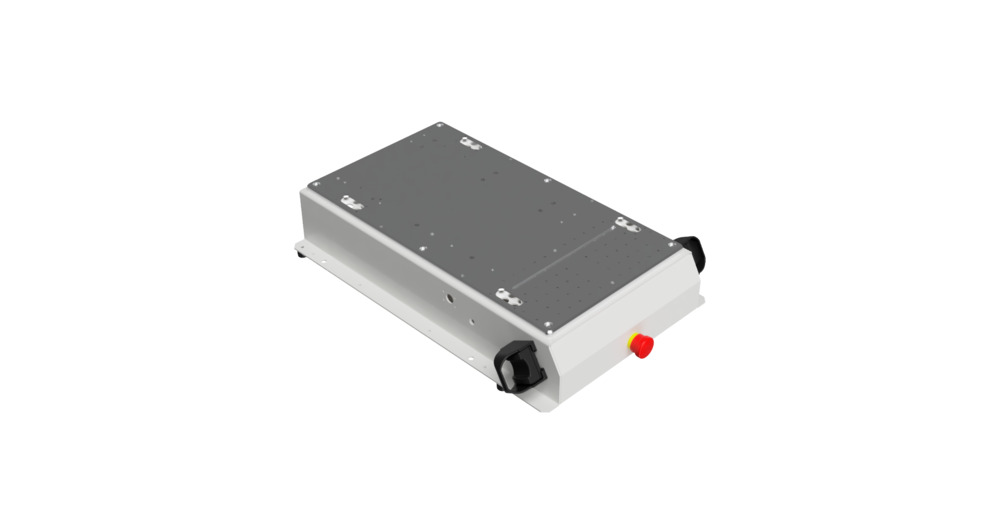

- Placement Accuracy: +/- 0.35mm (0.014″) or better (component dependent)

- Optional EP Package Accuracy: +/- 0.1mm (0.004″) or better (component dependent)

- 16-Key Applicator Interface Module (AIM) with LCD Display for Operator Input

More Popular Configurations

Design Your System

Accessories and Upgrades