Electric Tamp Modules are available as a standard option on all Nautilus Systems, Inc. (NSI) PL100 and PL165 Applicator products. Key benefits of the Electric Tamp include rapid acceleration and deceleration, digital control of the tamp motion profile, elimination of all pneumatic cylinders and associated sensors and flow controls, and reduced compressed air consumption. Compressed air is required only to operate the vacuum generator modules in these Applicators.

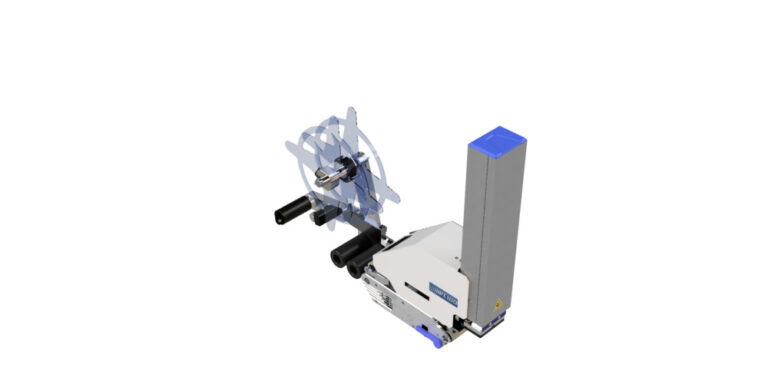

PL100i-ET200

The PL100i-ET200 Applicator provides capacity for die-cut adhesive components up to 100 x 100mm in size and is configured specifically for integration with automated assembly systems. Typical placement accuracy is +/- 0.35mm (+/- 0.014″).

To learn more about the PL100i-ET200 CLICK HERE.

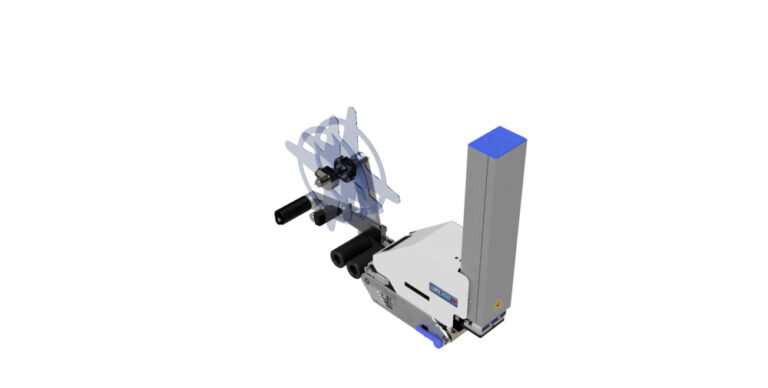

PL100EPi-ET200

Highest Accuracy

The PL100EPi-ET200 Applicator provides capacity for die-cut adhesive components up to 100 x 100mm in size and is configured specifically for integration with automated assembly systems. Typical placement accuracy is +/- 0.1mm (+/- 0.004″).

To learn more about the PL100EPi-ET200 CLICK HERE.