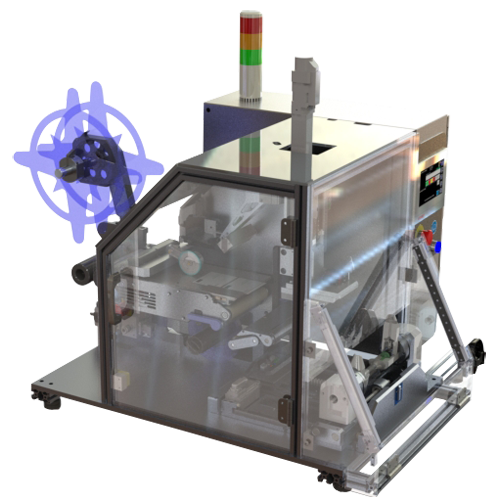

Description

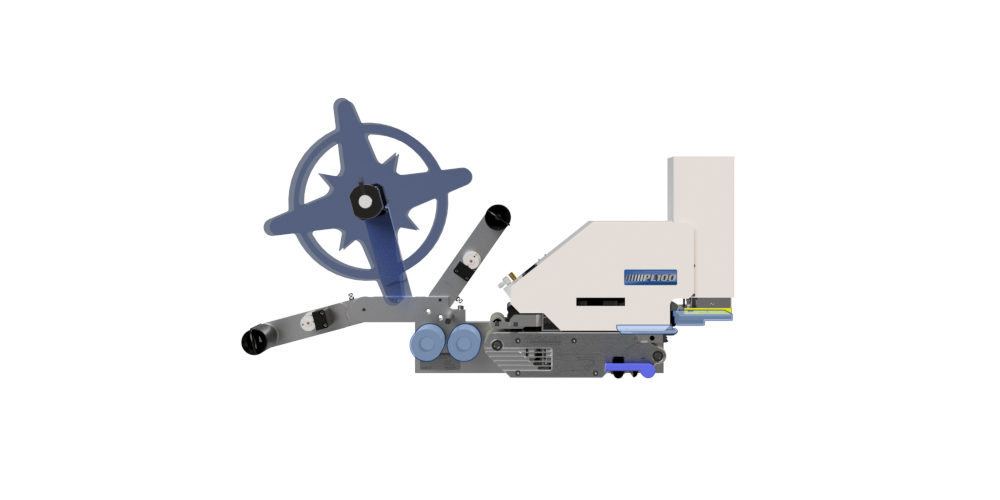

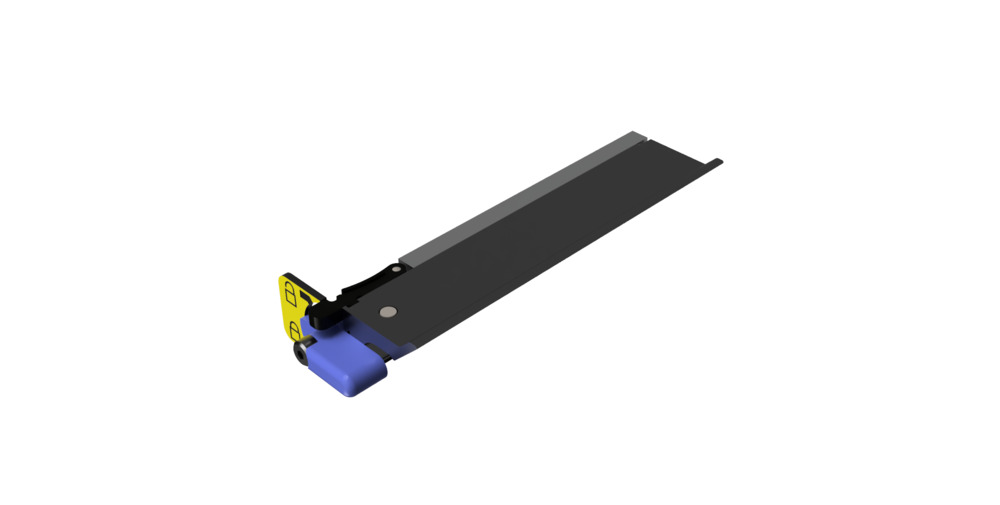

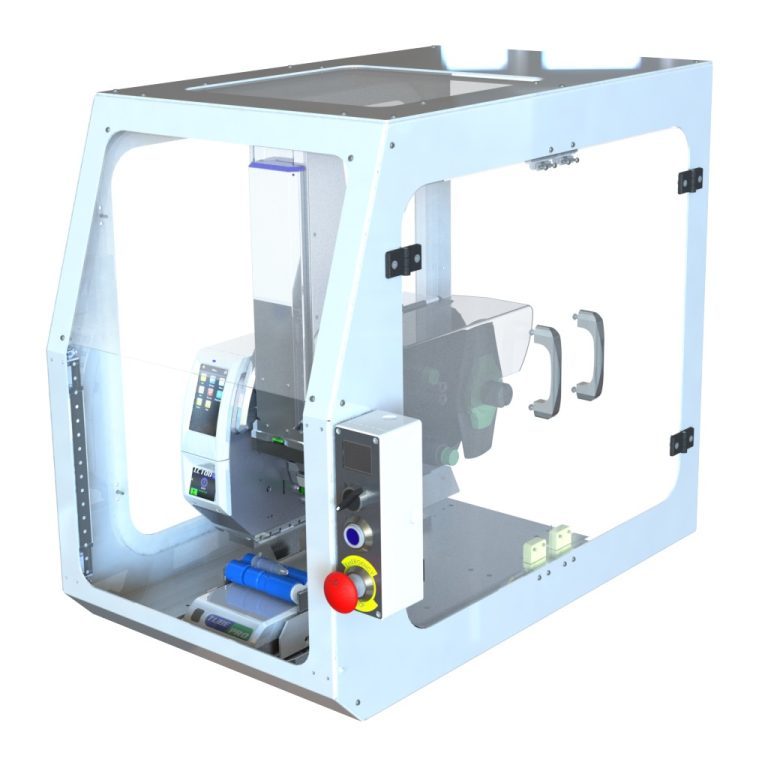

We have configured a special version of our PL Applicator products specifically to meet needs in the Pharma, Life Scences, and Healthcare industry. This PL Applicator includes a specialized vacuum chuck configuration that allows us to feed and inspect a label ‘just in time’ as that label is to be applied. Any labels that fail the optional inspection can then be handled by the Vacuum Chuck and placed in a controlled location for automatic handling such that labels are always controlled. Labels that pass inspection are automatically delivered by the Vacuum Chuck to the substrate component or device and applied depending on the method required: ‘flat apply’ or wrapping.

Features

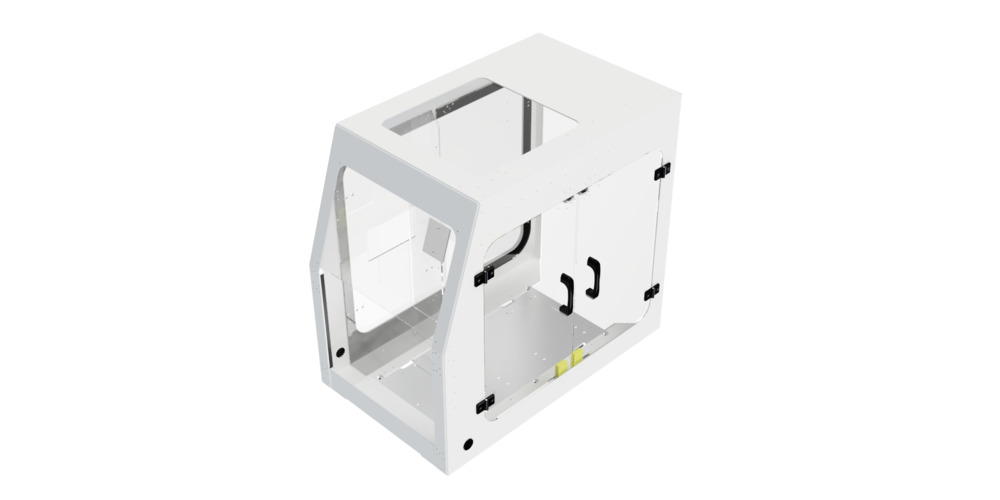

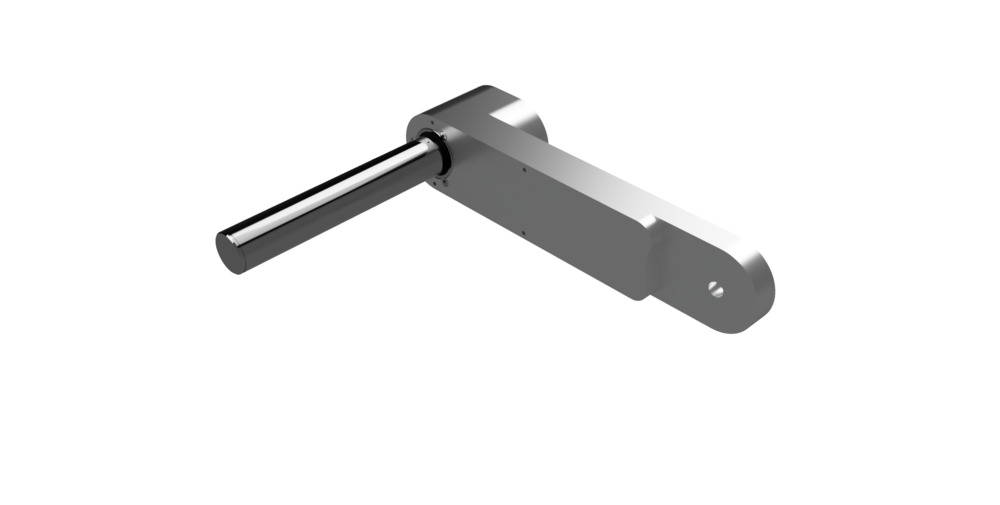

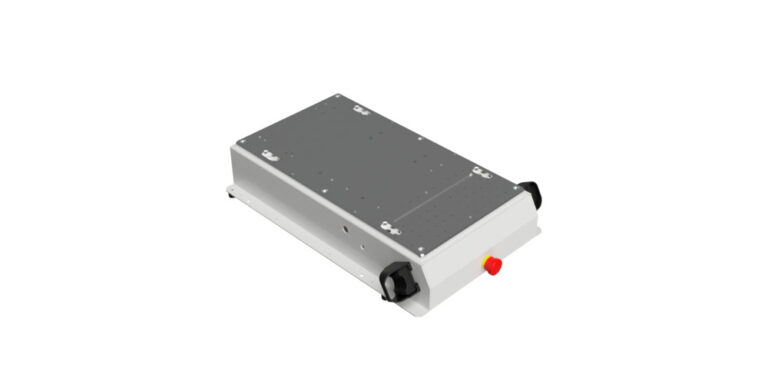

- Base Unit includes Tamp (150mm stroke), Payoff, and Powered Take-Up (Rewind)

- Configured for Integration into Automation

- Rapid Changeover Features

- Maximum Affordability

- 100 x 165mm Component Capacity

- Any Shape, Any Material, Multiple Simultaneous Placements

- Placement Accuracy: +/- 0.35mm (0.014″) or better (component dependent)

- Optional EP Package Accuracy: +/- 0.1mm (0.004″) or better (component dependent)

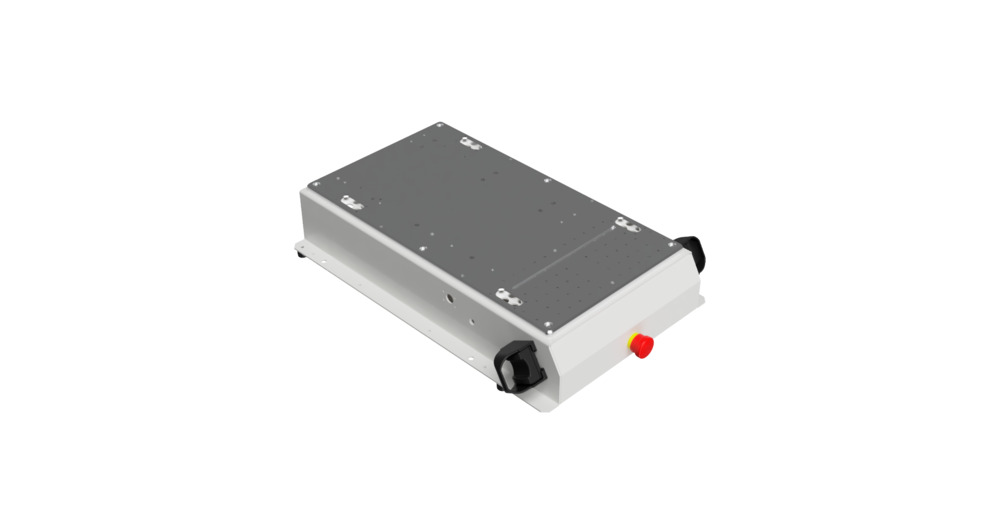

- Optional Dual Force Tamp for increased Tamp force

- 16-Key Applicator Interface Module (AIM) with LCD Display for Operator Input

- Optional Secure AIM limits accessibility to approved personnel

More Popular Configurations

Design Your System

Accessories and Upgrades