Category: Products

-

PL165EPr Feeder

Description The “All-Electric” PL165EPr Feeder provides a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. No pneumatics simplifies setup and maintenance. It provides capacity for components up to 100 x 165mm in size. The EP Package provides maximum accuracy with measured results as good as +/- 0.035mm.…

-

PL165EPr-C Compact Feeder

Description The “All-Electric” PL165EPr-C is Feeder our compact version of the PL165EPr unit. It provides a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. No pneumatics simplifies setup and maintenance. It provides capacity for components up to 100 x 165mm in size. The PL165EPr-C is configured specifically…

-

PL165i Applicator

Description The PL165i Applicator provides highly accurate and reliable placement of virtually any shape of die-cut adhesive component. It provides capacity for components up to 100 x 165mm in size. The PL165i Applicator is configured specifically for integration into automated assembly solutions. It includes all of the hardware necessary for operation including a pneumatic precision-guided…

-

PL165i-ET200 Applicator

Description The PL165i-ET200 Applicator provides highly accurate and reliable placement of virtually any shape of die-cut adhesive component. It provides capacity for components up to 165 x 165mm in size. The PL165i-ET200 Applicator is configured specifically for integration into automated assembly solutions. It includes all of the hardware necessary for operation including an electric precision-guided…

-

PL165i-SS (Side Scan) Applicator

Description The PL165 Applicator with Pneumatic Tamp is available with a Side Scan Tamp module. The PL165i-SS Applicator or the PL165EPi-SS Applicator can be selected for your application. The Side Scan Tamp module provides an additional axis of motion control to allow the Tamp to move on a horizontal plane. This module is typically implemented…

-

PL165r Feeder

Description The “All-Electric” PL165r Feeder provides a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. No pneumatics simplifies setup and maintenance. It provides capacity for components up to 100 x 165mm in size. The PL165r is configured specifically for integration with external Robotic or Picker devices. It…

-

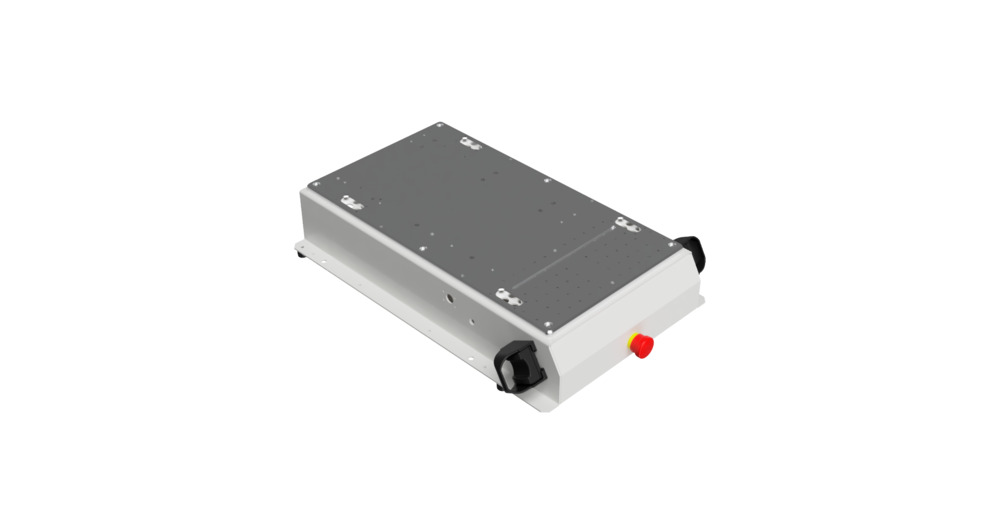

PL165r-C Compact Feeder

Description The “All-Electric” PL165r-C Feeder is our compact version of the PL165r unit. It provides a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. No pneumatics simplifies setup and maintenance. It provides capacity for components up to 100 x 165mm in size. The PL165r-C is configured specifically…

-

Radian Pi Servo Grippers and Servo Linear Actuators

Description Based on our Radian Pi Motor technology we have developed a series of micro grippers that provide major benefits for automation requirements. Features

-

Radian Pi Servo Motor Actuators

Description In order to develop motion hardware to meet the very specific requirements of our applicator and lab automation products, Nautilus Systems, Inc. has developed a series of specialized servo motors that we have made available to the automation market. These servo motors, which can be accurately described as ‘micro’ or even ‘nano’ servo motors…

-

Robot Base

NSI is pleased to offer system integration incorporating robotics. A standard Robot Base will include a robot, either 6-axis or SCARA, along with a standard LC or PL Applicator(s), and customized tooling required to provide the requested functionality. Robot Base projects are often customized systems, please reach out to NSI for information regarding how we…