Nautilus Systems, Inc. (NSI) All-Electric PL100 Robot Mode Feeders are configured specifically for integration with external Robotic or Picker devices to provide a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. The Robot Mode Feeders include all hardware necessary for operation including the base Feeder, a Payoff assembly, and a powered Takeup (rewind) assembly.

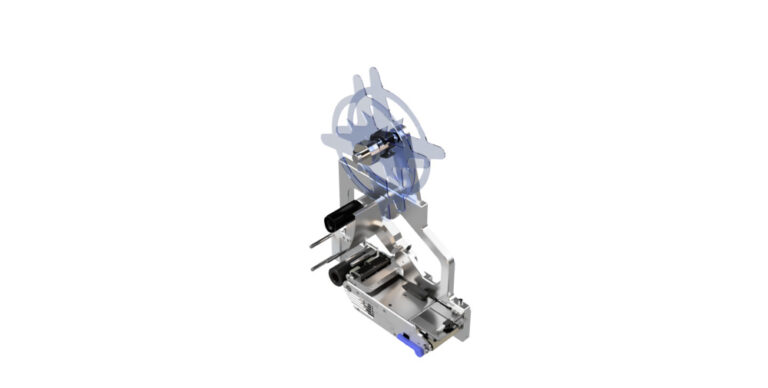

PL100r

The PL100r Feed and Peel System provides capacity for die-cut adhesive components up to 100 x 100mm in size and is configured specifically for integration with external robotic or picker systems. Typical feed accuracy is +/- 0.35mm (+/- 0.014″).

To Learn more about the PL100r CLICK HERE.

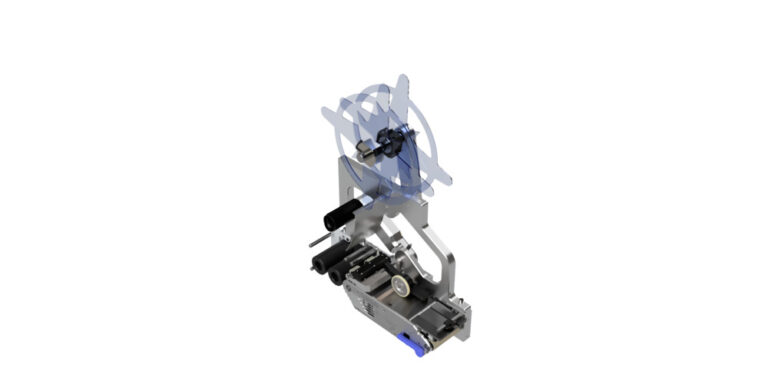

PL100r-C

The “All-Electric” PL100r-C is our compact version of the PL100r unit. It provides capacity for die-cut adhesive components up to 100 x 100mm in size and is configured specifically for integration with external robotic or picker systems. Typical feed accuracy is +/- 0.35mm (+/- 0.014″).

To Learn more about the PL100r-C CLICK HERE.

PL100EPr

The PL100EPr Feed and Peel System provides capacity for die-cut adhesive components up to 100 x 100mm in size and is configured specifically for integration with external robotic or picker systems. Typical feed accuracy is +/- 0.1mm (+/- 0.004″).

To Learn more about the PL100EPr CLICK HERE.

PL100EPr-C

The “All-Electric” PL100EPr-C is our compact version of the PL100r unit. It provides capacity for die-cut adhesive components up to 100 x 100mm in size and is configured

specifically for integration with external robotic or picker systems. Typical feed accuracy is +/- 0.1mm (+/- 0.004″).

To Learn more about the PL100EPr-C CLICK HERE.